-

AMRs are equipped with real-time obstacle detection and rerouting capabilities to navigate around unexpected objects or changes in the environment.

-

Yes, modern AMRs are designed to integrate with WMS, ERP, or other systems for seamless operation.

-

Regular updates to software, checking sensors and batteries, and performing routine diagnostics ensure AMRs run smoothly.

-

Implementation is typically straightforward. Unlike traditional automation systems, AMRs don’t require extensive infrastructure changes. The setup involves mapping the warehouse and integrating the robots with existing systems like WMS (Warehouse Management Systems).

-

Yes. AMRs come with advanced safety features like obstacle detection, automatic braking, and collision avoidance, ensuring they can work alongside humans safely.

-

AMRs use advanced navigation systems like SLAM (Simultaneous Localization and Mapping) to move freely without fixed tracks or pre-installed markers, unlike AGVs, which follow fixed paths like magnetic strips or wires.

-

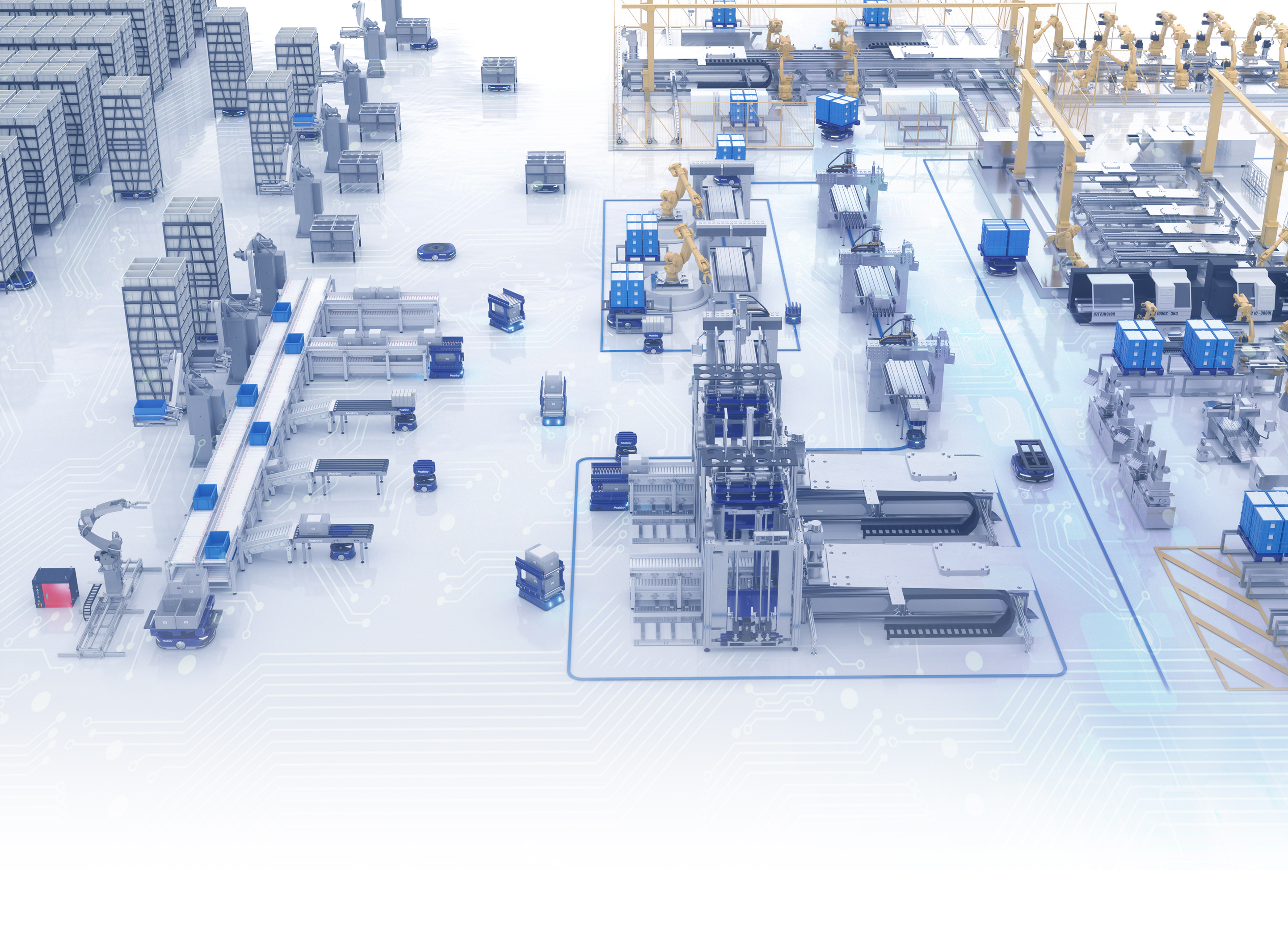

AMRs are mobile robots equipped with sensors, cameras, and software to navigate a warehouse autonomously. They handle tasks like transporting goods, picking items, or sorting packages, boosting efficiency and reducing manual labor.